Stylepark Interview with the founder and managing director Dr.-Ing. Florian Ilchmann

Anna Moldenhauer: Dr. Ilchmann, you developed the idea for Ambright 13 years ago and have since worked hard to bring it to market maturity. How did the concept come about?

Dr. Florian Ilchmann: At that time, I studied electrical engineering at the Technical University of Munich and was then given the opportunity to do a doctorate in the field of medical electronics. It was through my doctorate that I came into contact with Siemens. At that time, they were looking for an optimal solution for the illumination of a computer tomograph, and I was confident that I could develop it. In order to be able to face Siemens in China with my idea, I founded Ambright, but still without employees and without own premises. With the possibilities that my chair provided me technically, I was able to build a sample for the presentation - and this convinced Siemens. The product was then put into series production, and to this day we are a technology supplier for Siemens Healthineers, among other things for the lighting technology in mammography devices, X-ray devices or in fluoroscopy. This knowledge helps us enormously, because the lighting and luminaire systems for medical devices have to meet particularly high requirements. For Ambright, this path was a very good school for which I am enormously grateful.

Together with your team, you have developed a globally unique process that prints light automatically with extreme precision. The result is, among other things, the individual "SparkShapes" luminaires. How did these arise?

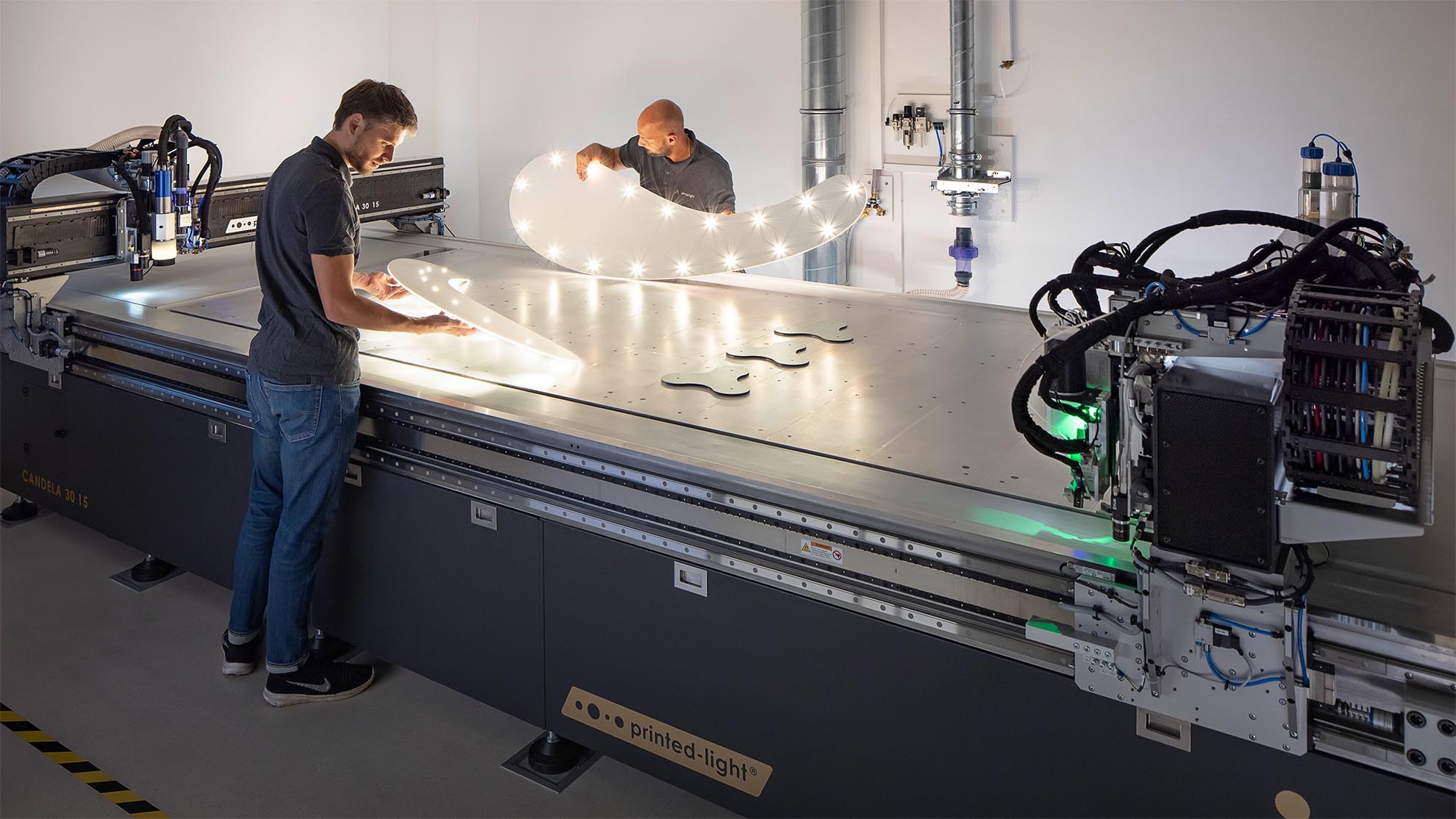

Dr. Florian Ilchmann: The name "printed-light" has come about over the years because we developed an additive platform technology for medical devices and then transferred it for other uses. The process we developed is used to be able to use electrical connectivity as a connecting bracket. Electronic components are normally integrated on circuit boards, except that the board was basically designed to have a high component density and be as small as possible. For applications that require you to manufacture as large as possible, but only have a low to medium component density, we therefore developed our own technology. That was the foundation stone for collotype printing. After the first few years with a laboratory system, we were able to start up the first large series production system "Candela" last year. I am very proud of our team.

How exactly does the process work?

Dr. Florian Ilchmann: In detail, the process works like this: First, we place normal electronic components that would otherwise be placed on circuit boards. Once these components are fixed in place, we connect them electrically by applying copper additively in a high-frequency process. And these copper conductor tracks practically run from one component to the next, forming the conductor paths - just like on a circuit board, only spatially much larger. This allows us to build large-format electrical circuits and electrically interconnect a whole range of active components. With the possible implementation on different materials such as plastics, metals, paper or foils, we can, among other things, build customized luminaires. We embed the active components such as LEDs, drivers or suspension points and optics in a specially developed composite material - in other words, everything that is necessary for a luminaire to function technically. Once the components have been connected, an individual shape is milled out of the substrate material. This gives us a manufacturing process that allows us to respond individually to the shape, but also to the lighting design of a luminaire, because users can specify in each case where the light sources are to be located. The number and position of downlights and uplights can also be determined as required. In this way, we can produce individual one-off pieces in a single process, where not only the shape of the luminaire but also the amount of light or the position of the feed follows the customer's wishes.

What other possibilities do the "SparkShapes" offer?

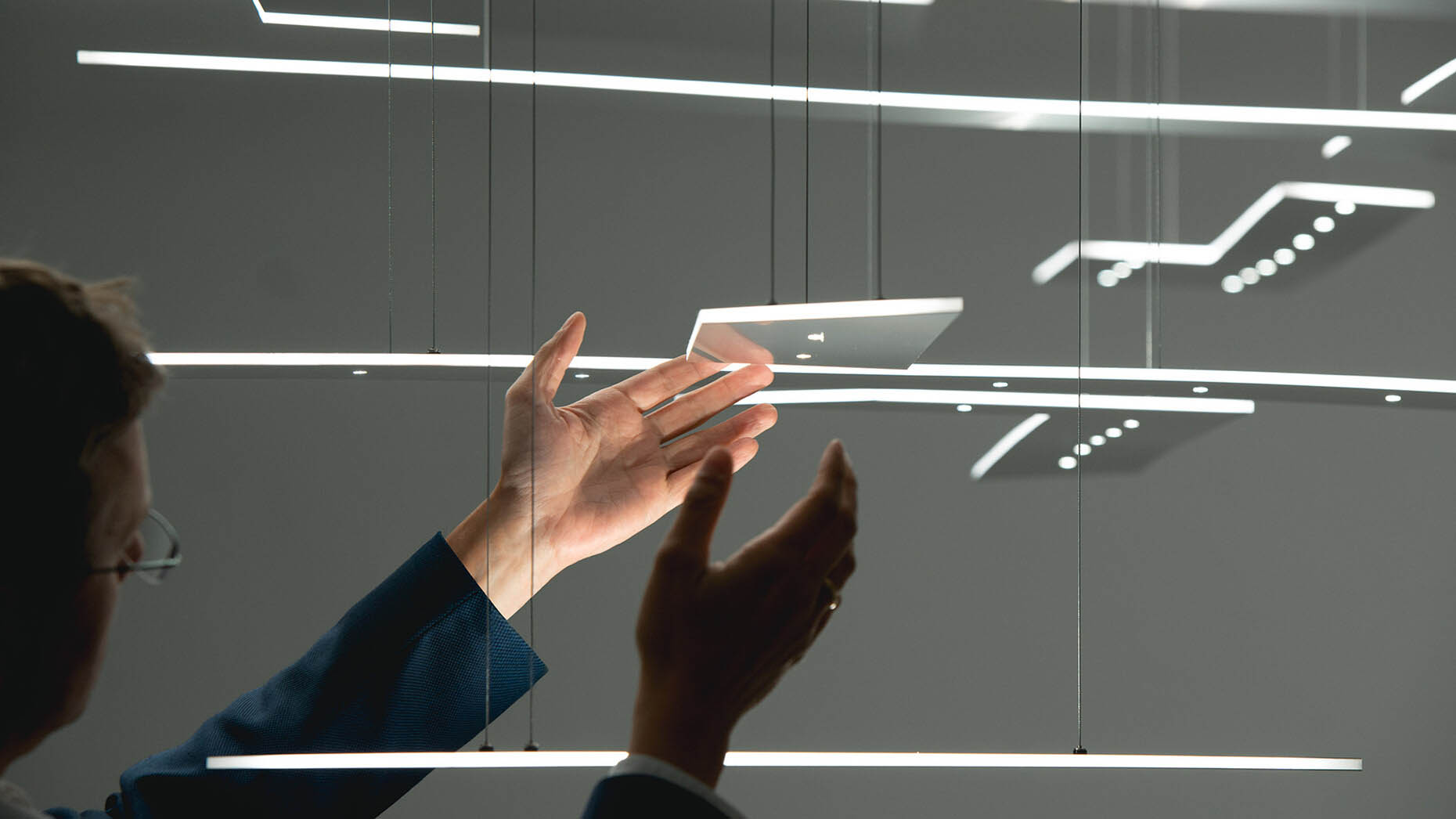

Dr. Florian Ilchmann: Our approach is very early stage, because we want to animate the designers to plan with our product. The existing offer of the established luminaire manufacturers comes from the catalog. Our product is designable, more digital and more agile: With this technology, virtually any shape can be made in any size. We want to emphasize the profession of designing and offer our customers a lighting tool to use this freedom. Their own signature should be reflected in the luminaire. Basically, with "SparkShapes" we can produce a catalog item according to specific ideas and place it in different dimensions and orientations - even multi-layered, spatial sculptures can be formed with it.

How does the configuration work?

Dr. Florian Ilchmann: For the design of the "SparkShapes" we have written the software tool LightSketch, which allows customers to draw themselves. It is thus possible to import a design draft from a CAD or graphics program into our digital tool, place the light sources according to their wishes and immediately find out the technical data of the luminaire - how many lumens, how many lux at what distance, what would it cost to realize the design? What is the effect if I want a different color temperature or surface? Depending on the input, the data changes in real time - feasibility check included. After finalization, users receive a data package that is on par with that of a traditional luminaire manufacturer: 14 pages of information, including inspirational images and 3D views. We want it to be fun to design a luminaire without having to request a new lighting calculation for every change in parameters. The high level of digitalization is an important step and unique in the industry in its diversity. It is not a configurator that provides finite combinatorial options - in terms of design, LightSketch offers unlimited possibilities.

With this enormous freedom of product design, how can you still integrate a recognition value for your company?

Dr. Florian Ilchmann: This is a very important point: We achieve a recognition value not only through the consistently slim design, but also through our illuminated edge - the third light component of a SparkShape. Regardless of the individual shape, it forms a recurring element. Thus, the luminaire is recognizable as one made by Ambright, regardless of the geometry. We were inspired by discussions with architects who wanted an elegant finish for the edges. We therefore developed a filigree element that contributes to the visual impression that the luminaire floats in space.